Organize - Document - Plan - Automate - Automate - Analyze

A CMMS allows you to organize, document and plan all maintenance activities. From preventive maintenance scheduling to work order management, spare parts management and detailed reporting.

What is a CMMS?

The CMMS (Computerized Maintenance Management System), also known as CMMS (Computerized Maintenance Management System), is a technological tool designed to facilitate the management of maintenance activities within an organization. Through this system, companies can optimize their maintenance processes, improve operational efficiency and reduce costs associated with downtime and equipment wear and tear.

Why implement a CMMS?

The implementation of a CMMS provides numerous benefits to organizations looking to improve their maintenance management. Some of the main reasons for adopting this system are highlighted below.

Optimize time and resources

A CMMS automates many of the often time-consuming manual tasks, such as scheduling work orders and tracking spare parts inventory. This not only saves time, but also reduces human error, ensuring that technicians work more efficiently.

Improve maintenance planning

The preventive maintenance is critical to avoid costly unplanned downtime. With a CMMS, organizations can automatically schedule preventive maintenance tasks based on time or equipment usage. This ensures that necessary inspections and repairs are performed on time, preventing unexpected failures.

Centralize information

A CMMS stores all maintenance information in a single database accessible to all authorized users. This facilitates quick access to historical information, such as past repairs, suppliers and maintenance costs, which in turn improves decision making.

Improve inventory management

The system enables precise control of spare parts inventory, preventing shortages of critical parts or unnecessary overstocking. This is essential to reduce costs and ensure that technicians always have access to the parts they need.

Implement a CMMS is undoubtedly a strategic decision for any company seeking to improve its maintenance and operational efficiency. The implementation of a CMMS not only improves internal efficiency, but also provides a significant long-term return on investment.

Benefits of implementing a CMMS

There are many tangible and intangible benefits of acquiring a CMMS in your company.

What are the technology trends in maintenance management systems (CMMS)?

CMMS 100% systems on the cloud

The adoption of CMMS 100% systems in the cloud has grown exponentially, offering greater accessibility, flexibility and cost reduction. These systems allow access to information from anywhere with an internet connection, eliminate the need for physical infrastructure and provide automatic updates. They are ideal for companies seeking to manage their operations globally and optimize resources without the need for dedicated servers.

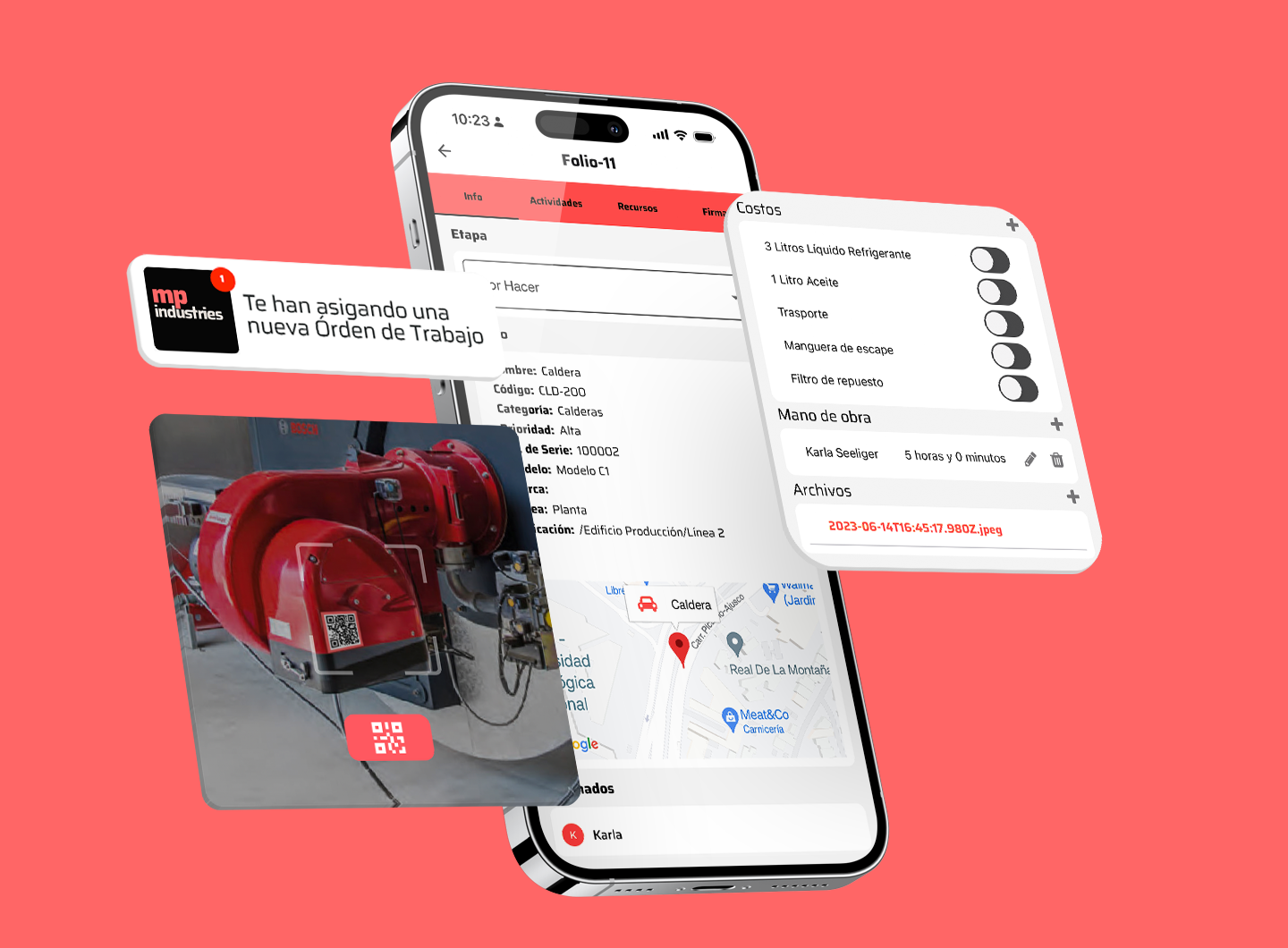

IoT (Internet of Things) Integration

CMMS integration with IoT devices is a significant trend that enables real-time monitoring of equipment and assets. IoT sensors send automatic alerts to the system when they detect anomalies, facilitating a predictive maintenance approach, which helps prevent failures, reduce downtime and extend asset life.

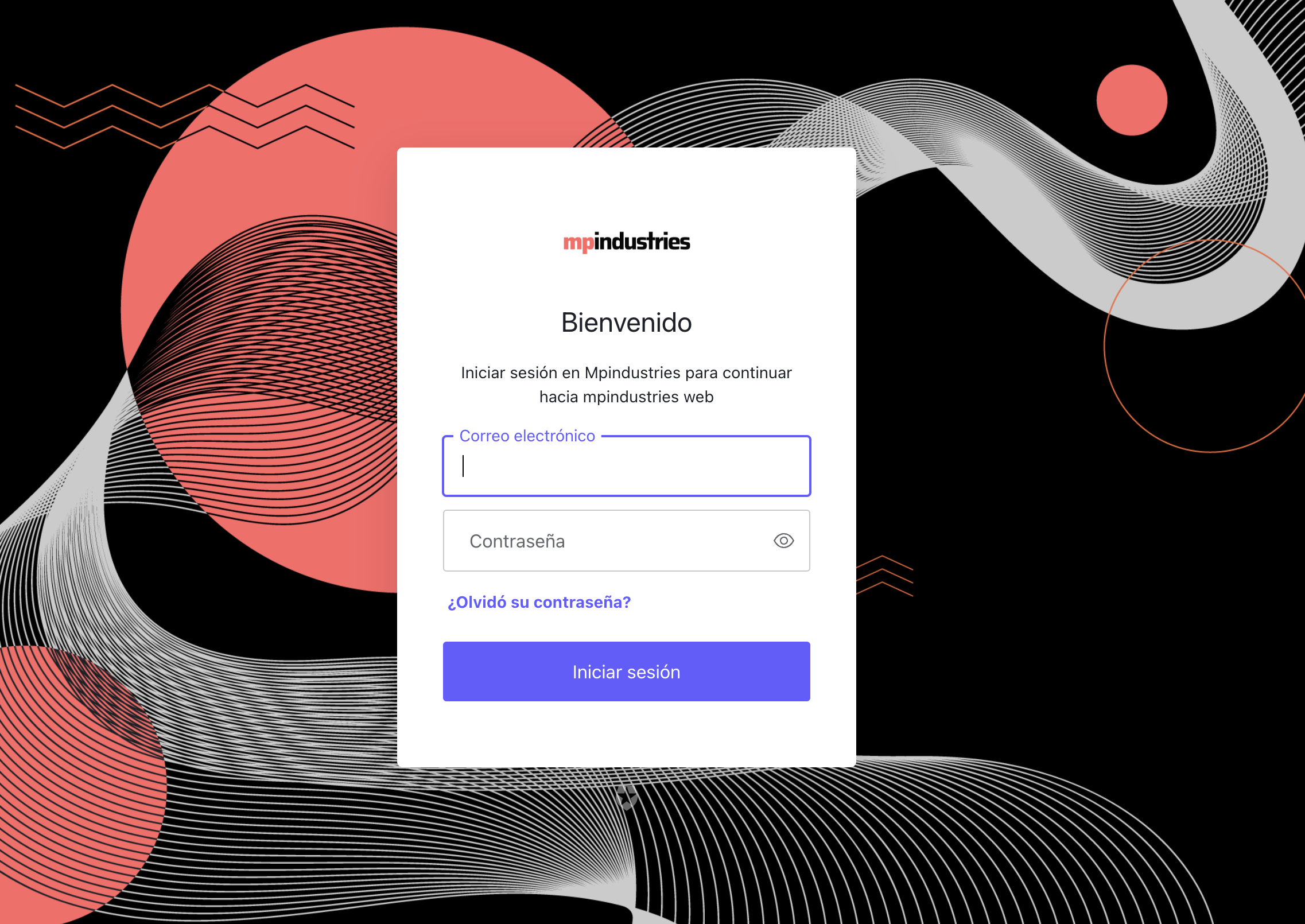

Schedule a live tour of MPindustries and get a 30-day BUSINESS account.

FREE CMMS

Take the first step towards automation with MPindustries: Implement our free CMMS today - follow the steps to get your free account and optimize your maintenance management!

1° Schedule an Online Demo with a consultant to get to know our CMMS and its applications in broad strokes.

2° Create a free account and configure the CMMS according to your needs. The free account is perfect for small businesses or to start an implementation.

*To know the difference between our versions and their functionalities, please download our comparative table.

3° If you want to take advantage of all the functionalities, ask your consultant for a 30-day trial of the Version Business.

*NOTE: At any time you can schedule an appointment with our Customer Success team to help you implement our Free CMMS.

Do you have a company that provides maintenance services?

If you are a company that provides maintenance services to different customers, we recommend you to know about MPservices. The most complete FSM (Field Service Management) platform on the market.

Optimize your company's operations and automate maintenance activities with our cloud-based CMMS system.

Increase your recurring revenue and the productivity of your technicians with the first Field Service Software (FSM) created for maintenance services companies.

Leading software company in Maintenance Technological Solutions with more than 30 years of experience. Committed and oriented to customer satisfaction.

© 2025 MPtotal, MPindustries and MPservices are registered trademarks of Software para Mantenimiento MP SA de CV.